Thermoplastics are almost inevitable in today’s world. From packaging and storage materials to consumer goods, medical equipment to machine parts, electrical/electronic components to automotive covers, they are used everywhere. Let us take a look at the most predominant applications of thermoplastic polymers.

Automobile industry:

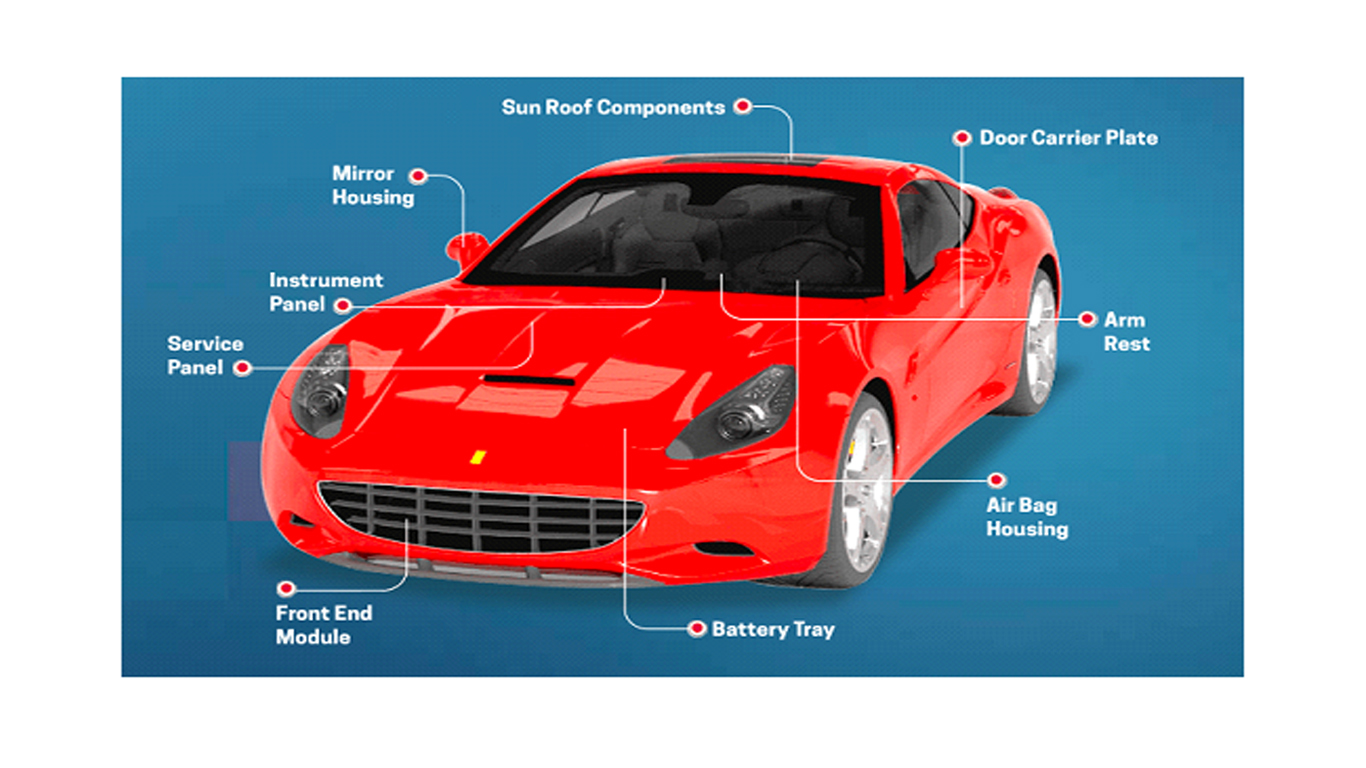

The automobile industry tops the chart when it comes to usage of thermoplastics. Of all the compounds used, polypropylene plays an important role in this industry. Its improved strength, stiffness and thermal capacity allow for its use in automotive bumpers and battery boxes. For insulation and seating applications, rigid polyurethane foams and flexible polyurethanes are used respectively. The shiny and impervious surface of ABS makes it suitable for dashboards, covers and linings in the car interiors. A modern PV carries about 75 Kg of Plastics, thereby replacing 8 times its weight of steel resulting in improved fuel efficiency.

Electrical Applications:

Thermoplastic polymers with good thermal resistance are used for electrical insulation. Polystyrene (in the form of expanded polystyrene foam), polypropylene and polyvinyl chloride(PVC) are used for this purpose. Thermoplastics are used in the lighting systems of aircraft cabins too.

Add our electrical MCB photo that we put on the website.

Mechanical applications:

Nylons exhibits high strength, durability and resistance to abrasion. For this reason, it is used for the manufacture of gear wheels, power tool casings and other mechanical parts. They are also used for making machine screws. In sliding parts of machines which are subjected to friction, a thermoplastic polymer called Teflon is used as a lubricant, in the form of ball bearings, bushings and gears.

Medical Applications:

Thermoplastic elastomers are used widely in medical equipment because of their high degree of purity, recyclability, excellent elasticity, ease for sterilisation and reasonable cost. They are used in syringes, medical tubing (catheters, drainage tubes, tourniquets, etc.), glucose measuring devices (vial caps, soft-touch cushioning, gaskets,etc.), surgical elastomer wipes, disposable surgical gowns, etc. Other types of polymers, like ultra-high molecular weight polyethylene, are used in making artificial joints.

Textile Industry:

Owing to its capacity to stretch, nylon, especially Nylon 6,6 is used in making fabrics and upholstery like curtains and carpets. On the industrial side, flak vests, parachutes, conveyor belts, seat belts, tarpaulins, etc. are manufactured using nylon, and even womens’ stockings are made out of nylon.

Packaging Industry:

Thermoplastic polymers, when adopted for packaging, are lightweight, safe and hygienic, extremely convenient for use and also aid with preservation. Polypropylene sheets are used for storage boxes and folders, while Polyamide 6 is explicitly used for medical packaging.

For further information contact info@formulatedpolymers.com